The week of the 12th of September was the 2022 edition of the IMTS (International Manufacturing Technology Show) in Chicago. 3D Etplus, as part of the Buffoli group, and in tandem with 3D Evolve, was present to showcase the high precision F1W printer. And along the way ran into cool little Desktop CNC machines.

Of course, 3D Etplus also managed to meet with other names, big and small, in the industrial manufacturing space.

Desktop manufacturing machines

Several so-called “desktop” machine manufacturers were present at IMTS. Obviously 3D printers, such as Formlabs, Azul 3D, 3DxTech, DesktopMetal and several others were there. However, besides those big names, the machines that really caught my eye were small, metal-cutting, desktop CNC machines with 3, 4 and 5 axes!

Small, precise, transportable, the Bantam Tools Desktop CNC machines

The Bantam Tools booth was constantly drawing a crowd. They were revealing their latest, smaller form-factor machine, the CNC Explorer. They were also showing off the updated version of their CNC Desktop machine, with an optional 4th axis. In terms of desktop machines for professionals, it’s a hard lineup to beat!

BantamTools Explorer CNC

The new Explorer CNC is a 3 axis CNC milling machine with a work volume of 150x100x70mm. The collet is an ER-11, giving ample compatibility with lots of bits available on the market. The machine is delivered with a probing pin (which uses electric connectivity), a 1/4″ (6.25mm) flat head bit, toe clamps, an alignment right angle, allen key, 2 collet keys, power and USB cables plus the free edition of their control software (the advanced version costs $300 per year).

Small, it is shipped with a pair of handles on the top of the chassis. And they will be shipped in Pelican cases for easy and secure transport no matter where you need it. At a list price of $3999, it isn’t yet in stock. Only pre-orders are open, with a shipping date planned for the 14th of november for North America only.

Bantam Tools CNC Desktop, 4th axis compatible

The big brother to the Explorer, the Desktop CNC has been updated and can now be fitted with an optional 4th axis. With a work volume of 175x225x85mm, the new modele gets the same black powder coated finish as the smaller Explorer, a deeper chip pan and a higher Z-axis pitch allowing for faster vertical movements.

Delivered with the same materials as its little brother, it’s not as easily transportable and costs $6499, which you can order immediately. There is a 4 week lead time, and unfortunately still no easy availability outside North America yet.

BantamTools is a young company that has already rebuilt its image. Currently leading the team is a name that 3D printing enthusiasts will recognize: Bre Pettis, cofounder and former CEO of Makerbot. Seen this way, BantamTools is aiming to bring the same level of domesticality to CNC milling as 3D printers have done for additive manufacturing. Except these machines will be able to directly work with materials otherwise hard to work with, like aluminum, brass and bronze!

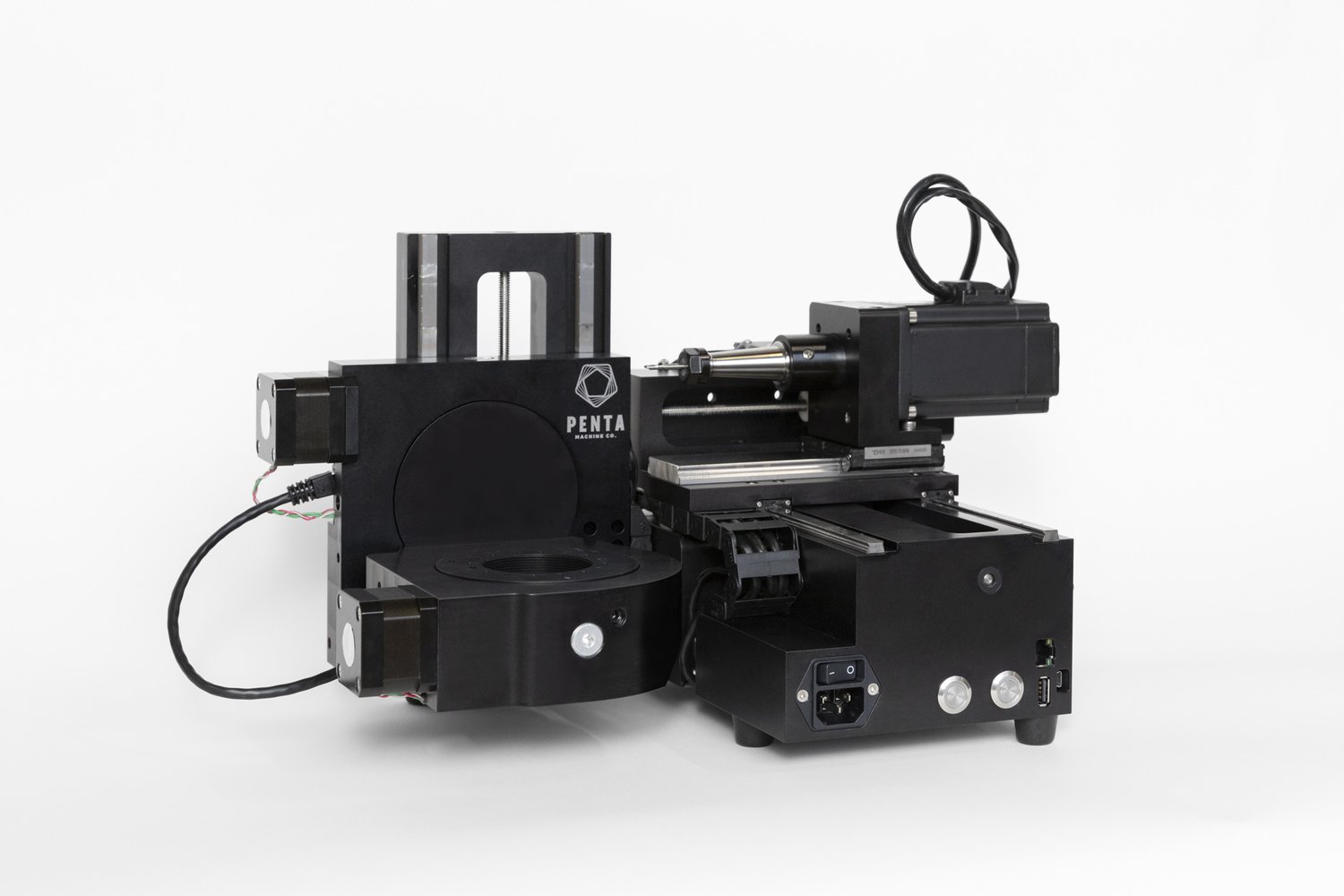

A 5 axis milling machine on the desktop, the Penta Machine Co. bet

Penta Machine was presenting at their booth (right next to BantamTools’) the two existing versions of their Pocket NC V2, a 5 axis desktop CNC milling machine. The first version, the Pocket NC V2-10, uses an ER-11 collet for the bits, with a spindle controllable between 2 and 10000 rpms. The work volume is 128.3×115.5×90.1mm and the machine is delivered with a healthy set of tools, as well as their software, Kinetic Control. With a retail price around $6500, this machine allows the use of an ER-40 collet to hold the material stock in place. This small desktop CNC milling machine is remarkably compact given its capabilities!

Primarily designed for the work of soft metals, such as brass, aluminum and polymers like Delrin, it can handle harder materials up to G5 titanium. It’s quoted as having a precision of 12.5µm and using bits up to 6.35mm (1/4″).

The slightly more powerful version of the Pocket NC is the V2-50CHB or V2-50CHK. The difference is only in terms of the choice of spindle and collet combinations. The 50CHB uses a CHB collet offering up to 2.5µm precision, but restricting tool diameter to 4mm. However they’re exchangeable using a quicklock lever, for quick tool swaps. The 50CHK uses a CHK type of collet, allowing tools up to 6.35mm (1/4″) and the same precision as the 50CHB. The spindle can range between 1000 and 50000 rpms. These two versions are higher priced, with the 50CHK being pricier than the 50CHB version.

In addition to their already sold small desktop machines, Penta Machine was showing off a prototype of a new 5 axis machine with more advanced capabilities. Not having a brochure or name for the machine, I can only describe briefly what I know about it. It’s using servos for closed-loop controls, a bigger build volume and a drawer-based tool-changer to completely automate part fabrication. It no longer sits on the desktop itself, but rather comes on a rolling stand and has a motorized enclosure. It also uses a coolant spray to keep the cutting tool cool and clean.

Penta Machine creates superb mills, and is partnering with MasterCam for the CAM software aspect of the files.

If one of these machines interests you, feel free to contact us!